NICKEL 201 Superalloys to UNS N02201

NICKEL 201 - Specification & Application

- UNS N02201 - Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

- ASME Code Case 2249 - Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

- BS 3072 – 3074 (NA12) - Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

- ASTM B 160 – B 163, B 366,B 725, B 730, B 751,B 775, B 829 - Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

- DIN 17740, 17750 – 17754 - Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

- ASME SB-160 – SB-163,SB-366, SB-725, SB-730,SB-751, SB-775, SB-829 - Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

- ISO 6207, 6208, 9723 – 9725 - Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

Chemical composition(wt.%) of NICKEL 201 grade: to UNS N02201

| Elements | Min.(≥) | Max.(≤) | Similar | Remarks |

|---|---|---|---|---|

| C | - | 0.02 | ||

| S | - | 0.01 | ||

| Si | - | 0.35 | ||

| Cu | - | 0.25 | ||

| Ni | 99 | - | ||

| Fe | - | 0.4 |

NICKEL 201 - Detail

Commercially pure (99.6%) wrought nickel essentially the same as Nickel 200 but with a lower carbon content to prevent embrittlement by intergranular carbon at temperatures over 600°F (315°C). Lower carbon content also reduces hardness, making Nickel 201 particularly suitable for cold-formed items.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3........................................................................0.321

g/cm3......................................................................... 8.89

Melting Range, °F ...................................................2615 – 2635

°C ...................................................1435 – 1446

Specific Heat, Btu/lb•°F ....................................................0.109

J/kg•°C........................................................... 456

Curie Temperature, °F ........................................................... 680

°C ........................................................... 360

Permeability ........................................................ Ferromagnetic

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.3

21 – 93°C, µm/m• °C............ 13.1

Thermal Conductivity, Btu • in/ft2•h•°F ........................... 550

W/m• °C.......................................... 79.3

Electrical Resistivity, ohm• circ mil/ft..................................51

µΩ•m..............................................0.085

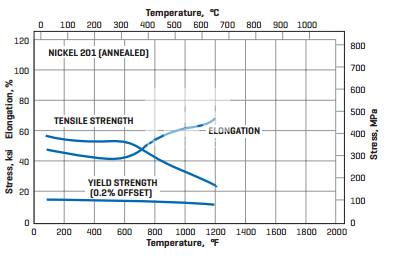

TYPICAL MECHANICAL PROPERTIES

(Annealed)

Tensile Strength, ksi.............................................................. 58.5

MPa............................................................ 403

Yield Strength (0.2% Offset), ksi...........................................15

MPa..................................... 103

Elongation, % ..............................................................................50

| Proof strength Rp0.2 (MPa) |

Tensile strength Rm (MPa) |

Impact energy KV (J) |

Elongation at fracture A (%) |

Reduction in cross section on fracture Z (%) |

As-Heat-Treated Condition | Brinell hardness (HBW) |

|---|---|---|---|---|---|---|

| 469 (≥) | 654 (≥) | 44 | 12 | 11 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 131 |

| Property | Density kg/dm3 |

Temperature T °C/F |

Specific heat J / kgK |

Thermal conductivity W/mK |

Electric resistance µΩ·cm |

Modulus of elasticity kN/mm2 |

Expansion rate |

|---|---|---|---|---|---|---|---|

| 965 (≥) | 235 (≥) | 21 | 34 | 41 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 214 | |

| Temp. °C/°F |

Creep strain limit (10000h) (Rp1,0) N/mm2 |

Creep rupture strength (10000h) (Rp1,0) N/mm2 |

|||||

| 327 | 528 | 191 |

Equivalent Grade

Equivalent Products

Product shapes we supply:

- Tool Die Steels in the NICKEL 201 Superalloys grade

- Stainless Steels - Special Steels in the NICKEL 201 Superalloys grade

- Square and Flat Steel in the NICKEL 201 Superalloys grade

- Coil Sheet in the NICKEL 201 Superalloys grade

- Bar and Hollow Bar in the NICKEL 201 Superalloys grade

- Forgings in the NICKEL 201 Superalloys grade

- Superalloy in the NICKEL 201 Superalloys grade

- Tube Pipe in the NICKEL 201 Superalloys grade

- Non-Magnetic Steel in the NICKEL 201 Superalloys grade

- Steels of Blade for Steam Turbine in the NICKEL 201 Superalloys grade

We can customize the production of NICKEL 201 grade, contact us for the best solution.

–sales@specificsteel.com