ASTM F75 CoCr Alloy Superalloys to ASTM F75-2007

ASTM F75 CoCr Alloy - Specification & Application

- ASTM F75-2007 - CoCr alloys are widely used within the orthopedics, aerospace, power generation and the dental fields.

CoCr alloys are widely used within the orthopedics, aerospace, power generation and the dental fields.

Chemical composition(wt.%) of ASTM F75 CoCr Alloy grade: to ASTM F75-2007

| Elements | Min.(≥) | Max.(≤) | Similar | Remarks |

|---|---|---|---|---|

| C | - | 0.35 | ||

| Si | - | 0.10 | ||

| Mn | - | 1.00 | ||

| P | - | 0.02 | ||

| S | - | 0.01 | ||

| Cr | 27.00 | 30.00 | ||

| Ni | - | 0.50 | ||

| Mo | 5.00 | 7.00 | ||

| W | - | 0.20 | ||

| Co | - | Bal | ||

| B | - | 0.01 | ||

| Al | - | 0.10 | ||

| Ti | - | 0.1 | ||

| Fe | - | 0.75 | ||

| N | - | 0.25 |

Mechanical properties of grade ASTM F75 CoCr Alloy grade: to ASTM F75-2007

Yield Strength,Rp 0.2(MPa)

| Condition | Min | Max | Similar | Note |

|---|---|---|---|---|

| 587 | 613 |

Tensile Strength,Rm(MPa)

| Condition | Min | Max | Similar | Note |

|---|---|---|---|---|

| 1037 | 1063 |

Impact,Kv/Ku(J)

| Condition | Min | Max | Similar | Note |

|---|

Elongation,A(%)

| Condition | Min | Max | Similar | Note |

|---|---|---|---|---|

| 17 | 23 |

Reduction of area,(%)

| Condition | Min | Max | Similar | Note |

|---|---|---|---|---|

| 18 | 22 |

Hardness

| Condition | Type | Min | Max | Similar | Note |

|---|

ASTM F75 CoCr Alloy - Detail

ASTM F75 CoCr is a non-magnetic Cobalt Chrome alloy exhibiting high temperature capability, strength, corrosion resistance, wear resistance as well as excellent biocompatibility.

CoCr alloys are widely used within the orthopedics, aerospace, power generation and the dental fields.

Machining

Parts produced using the Arcam EBM process demonstrate excellent machineability using any conventional machining process.

The F75 built material allow polishing to mirror-like finish for use as articulating surfaces in knee implants or other applications requiring superior surface finish.

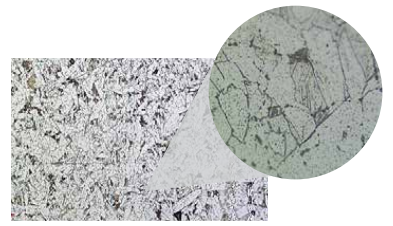

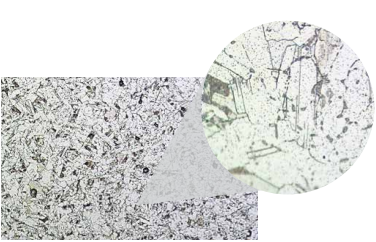

Microstructure

Manufacturing CoCr parts with F75 results in fully dense parts without weld lines in the material before or after HIP treatment. The images show the typical microstructure after HIP treatment with different magnification.

There is no porosity in both the horizontal and vertical cross sections

Horizontal cross section at 50x and 500x magnification

Vertical cross section at 50x and 500x magnification

Equivalent Grade

Equivalent Products

Product shapes we supply:

- Tool Die Steels in the ASTM F75 CoCr Alloy Superalloys grade

- Stainless Steels - Special Steels in the ASTM F75 CoCr Alloy Superalloys grade

- Square and Flat Steel in the ASTM F75 CoCr Alloy Superalloys grade

- Coil Sheet in the ASTM F75 CoCr Alloy Superalloys grade

- Bar and Hollow Bar in the ASTM F75 CoCr Alloy Superalloys grade

- Forgings in the ASTM F75 CoCr Alloy Superalloys grade

- Superalloy in the ASTM F75 CoCr Alloy Superalloys grade

- Tube Pipe in the ASTM F75 CoCr Alloy Superalloys grade

- Non-Magnetic Steel in the ASTM F75 CoCr Alloy Superalloys grade

- Steels of Blade for Steam Turbine in the ASTM F75 CoCr Alloy Superalloys grade

We can customize the production of ASTM F75 CoCr Alloy grade, contact us for the best solution.

–sales@specificsteel.com